Secrets to Building an Effective/Efficient Improvement Team

Which Improvement Team?

Many companies already have at least one improvement team. They might have:

- A Lean Team

- A Six Sigma Program

- A Quality Improvement Team

- A Safety Improvement Team/Committee

- An Asset Reliability Improvement Team

- An Operational Excellence Team

Did I miss one (or more)? There are many teams that could be added to the list. But even with the short list above, is the number of improvement teams at most companies is too long?

Do you notice something about these teams? That’s right. They are focused on different silos.

They:

- Focus on a particular kind of improvement (safety, quality, equipment reliability, …).

- Use different types of tools.

- Speak different languages (different program jargon).

- Require completely different training.

- Compete for similar resources.

- Don’t cooperate to gain mutual benefits.

- Don’t have a common set of measures.

- All want management’s limited attention.

That leads to crossed purposes. And the numerous programs duplicate effort and drain management’s attention.

How can energy and effort be saved? By starting a single program that uses common tools, the same (or similar) training, and works together to create a high-performance organization.

If that is too much to ask, at least the different programs could adopt the same root cause analysis tool.

How does this program work and what RCA tool should they adopt? Read on and find out.

Alignment: Similar Reasons for the Need to Improve

The main reason for any area (environment, safety, financial, efficiency, reliability, …) to need improvement is that area once had acceptable (or even excellent) performance, but the area stood still – it didn’t improve. The result? The competition passed them by.

Let’s look at an example…

Manufacturing Quality Example

This example comes from a US manufacturer. In the past, the quality of their product was good. It might not have been the industry leader, but it was competitive. They occasionally had customer complaints, late deliveries, parts out of specifications, rework, and failed to meet the customer’s schedule needs, but they were good at responding to trouble.

The company was running a tight ship because margins were declining due to overseas competition. Management was focused on cutting costs by reducing headcount, reducing training, and cutting other overhead costs. They weren’t investing in quality improvement and didn’t notice other companies that were implementing quality improvement and lean initiatives. They didn’t notice that the competitors’ quality (even the cheap, overseas competition) was improving and leaving them in the dust until they LOST THEIR BEST CUSTOMER.

The customer was nice. They gave the company a chance to try to win their business back. But the point they made was they could get better quality at a lower cost from the company’s competitors, who always delivered on time.

What did they do? They started an emergency quality improvement program. Everyone would focus on getting the part out on time, on spec, and at the same cost.

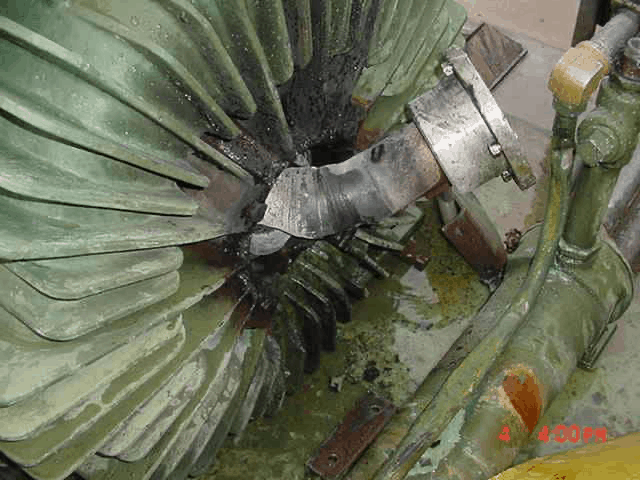

But then it happened. The company had a piece of equipment catch on fire and explode. It shut down the entire plant. Several people were severely injured, and one was killed. The OSHA regulators showed up to inspect and issue fines. One of the causes was the failure to perform maintenance on the equipment. Another was a human error in responding to the failure that made the fire spread and caused the explosion.

The plant manager was transferred (and eventually left the company), the ops manager and maintenance manager were replaced, and there were major layoffs of staff as the damage was evaluated. Six months later the facility was permanently closed.

What Was Wrong With This Companies Approach?

They focussed on a single problem without regard to overall performance. They thought they had a quality problem, but they really had a performance problem.

Their industry had moved along to higher levels of:

- quality,

- equipment reliability,

- human performance,

- safety, and

- operational excellence

The improvement the industry had achieved saved each company money that they could invest in further improvement efforts. The improvements allowed them to cut costs effectively (not by slashing staff and training, but by eliminating waste and mistakes).

The facility of our story was “suddenly” in trouble and responded with crisis management focussed on the crisis of the day (improve quality).

What was wrong with their approach? To improve quality, safety, equipment reliability, and financial performance, management needed to start improving BEFORE a crisis occurred. They needed to improve quality, safety, equipment reliability, environmental performance, production reliability, schedule performance, and cost control by investing in better equipment and human reliability. They needed to find the root causes of performance issues across all the different departments and become a high-performance, high-reliability organization. They needed to strategically invest in performance improvement that would yield improvement across the company (not just quality or finance/cost). They needed to focus on being one, two, or more steps ahead of the competition rather than chasing their tail in crisis management mode – reacting to the latest crisis.

But why would a company wait for an accident to improve? That’s the topic of THIS ARTICLE.

What Did They Need? Human Reliability & Equipment Performance Improvement in a Single Program

When someone makes a mistake (a human error), they aren’t planning on causing:

- An explosion

- An equipment failure

- A schedule slippage

- A part out of specification

- An environmental spill of hazardous chemicals

It’s just a mistake. What is the usual approach?

- Tell them to be more careful!

- Retrain them.

- Write a procedure (or make it longer).

- Or … Discipline them (or fire them) to set an example for everyone else.

Does this usual approach sound familiar?

And what if a piece of equipment breaks?

- Get maintenance to fix it!

- Replace it or replace the offending part.

- Keep more replacement parts on hand to make repairs faster.

- If it is a repeat failure (it’s failed 10, 20, or more times), maybe you should hire a consultant to make recommendations.

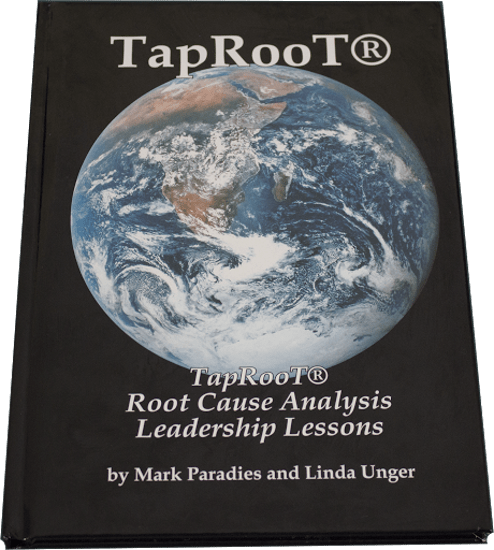

These approaches are used at many facilities. These facilities have a crisis management or blame vision (as described in Book 1: TapRooT® Root Cause Analysis Leadership Lessons).

You are living in the reactive crisis management mode. Reacting to failures one at a time. If so, at a minimum, you should be using advanced root cause analysis that:

- Uses a systematic process.

- Guides people to the root causes of human errors and equipment failures.

- Accurately finds the real, fixable root causes of incidents.

- Helps people find effective corrective actions to stop repeat failures.

- Can be used reactively but also can be used proactively.

- Helps management understand what needs to be done for short and long-term improvement to be achieved.

What is advanced root cause analysis? TapRooT® Root Cause Analysis is Advanced Root Cause Analysis. It provides the fundamentals of root cause analysis plus more! It provides a systematic, guided process for incident investigation (no matter what kind of incident we are talking about – safety, quality, process safety, equipment failure, schedule slippage, operational errors, or unintentional environmental releases).

Thus, when you adopt TapRooT® Root Cause Analysis as your standard root cause analysis process across an organization, you can:

- Use one language to discuss problems and their solutions.

- Adopt a single training course for all your analysts.

- Have a standard presentation for investigating problems that management will understand.

- Use the same techniques for minor and major investigations.

- Use the same techniques for reactive and proactive improvement.

- Be assured the technique works in all types of incidents (safety, quality, equipment reliability, production, construction, and environmental).

- Be assured the technique works in countries around the world.

But how does proactive improvement work? Read on…

Proactive Improvement

What is proactive improvement? Improving performance before an accident or incident happens.

How do you do that? By applying advanced root cause analysis in a program with audits/assessments focused on your highest-risk and highest-reward areas that need performance excellence.

The objective of the program is to identify potential problems that could cause safety, quality, process safety, equipment, schedule, operational, or environmental issues and fix the issues by addressing their root causes BEFORE the issue becomes an accident or incident.

Want to learn more about this process? We have a course about audits and proactive improvement – The 2-Day Audits & Proactive Improvement Using TapRooT® RCA.

What’s in the course? Here’s the course outline…

DAY ONE

- TapRooT® Process Introduction and Initial Audit

- SnapCharT® and Exercise

- Significant Issues and Exercise

- Root Cause Tree® and Exercise

- Generic Causes

- Corrective Actions and Exercise

DAY TWO

- The Root Cause Tree® and Preparing for Audits with Root Cause Exercise

- Audit Programs, Trend, and Process Root Cause Analysis

- TapRooT® Software Introduction

- Frequently Asked Questions about TapRooT® RCA

- Final Audit Observation Exercise

You can have this course at your site or attend one of our public courses.

For a quote for a course at your site CONTACT US.

To see when the next public 2-Day Audits & Proactive Improvement Course is, CLICK HERE.

Reactive and Proactive Improvement Aligned Across Silos

When you go beyond reactive improvement in a single silo to a broad combined reactive/proactive program across your organization, you need an improvement team. That team needs to span all the silos in your organization.

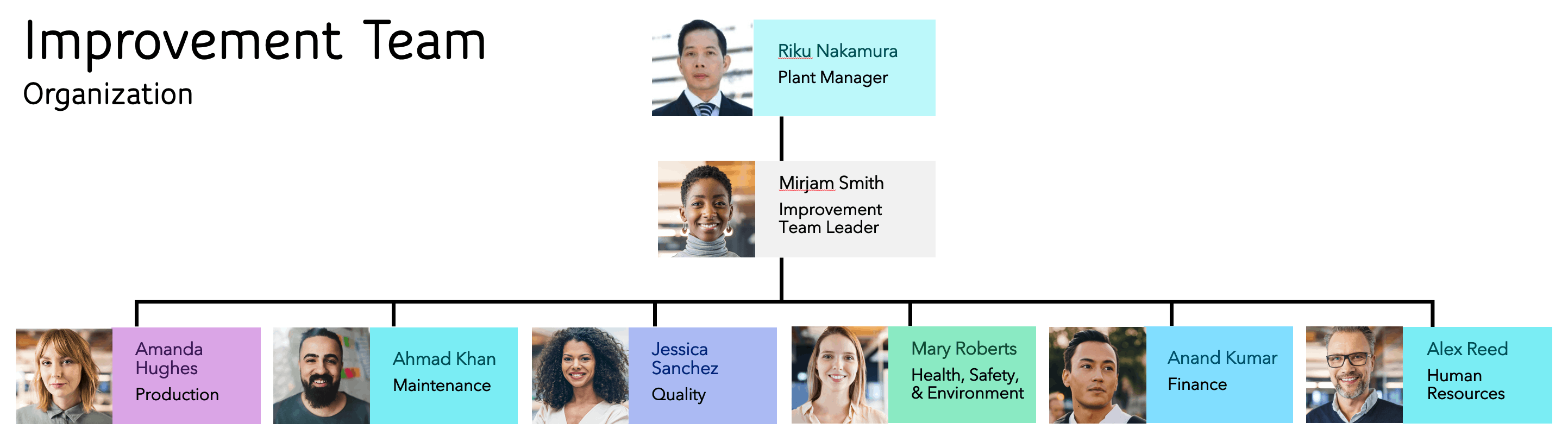

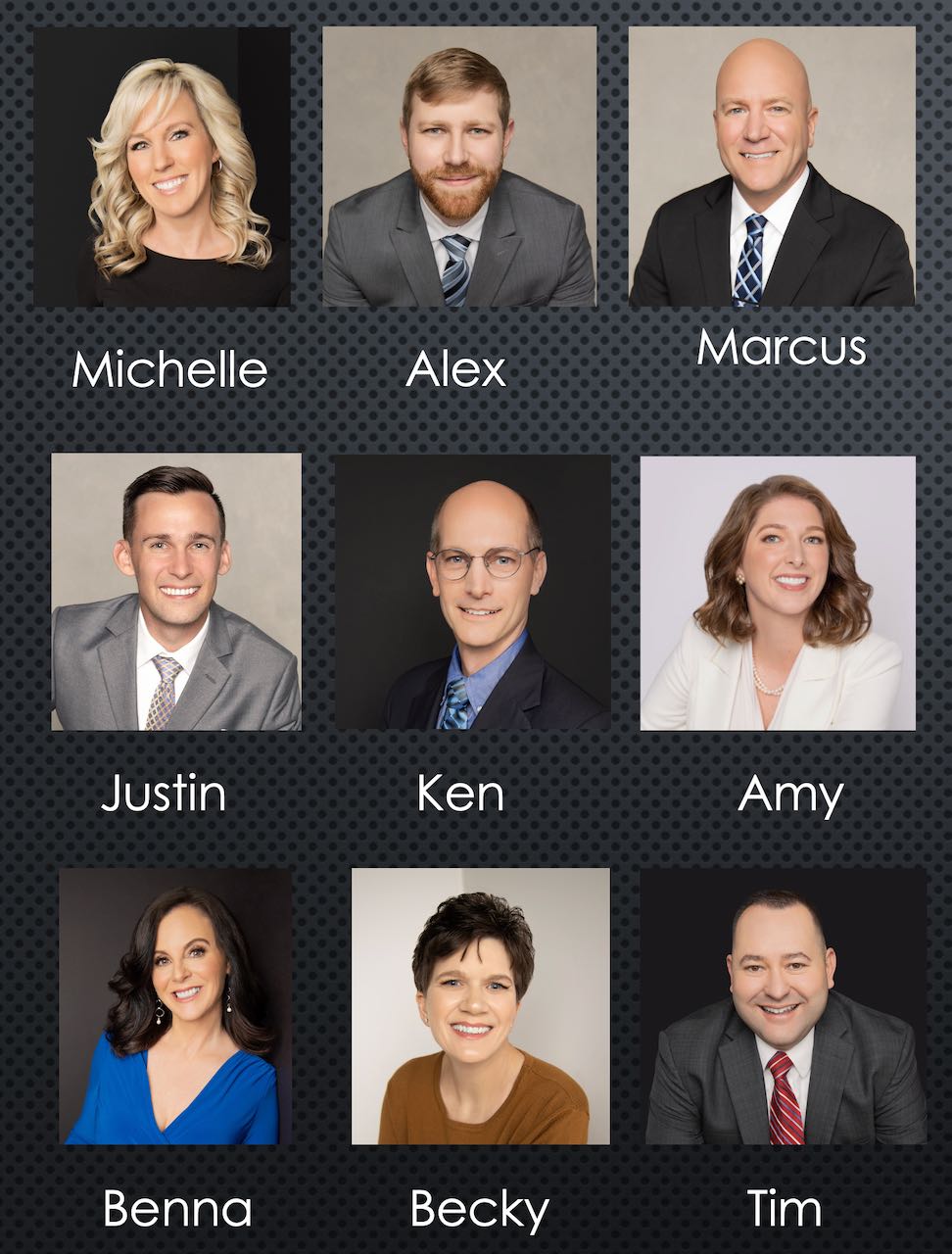

Here is an example structure of an improvement team at a large manufacturing plant…

In this case, the Plant Manager is the team’s sponsor.

Reporting to the sponsor is the Improvement Team Leader (a full-time job).

Each of the participating departments has a representative who could be the department head or their designated representative. Someone who can make commitments for the department head. In this example, the represented departments are:

- Production

- Maintenance

- Quality

- Health, Safety, and Environment

- Finance

- Human Resources

Being this representative in this example is just part of their job.

The participation by Production, Maintenance, Quality, and HSE reps seems obvious. But what are the roles of the Finance and Human Resources reps?

Finance helps develop the indicators/measures across all the programs. This includes money spent and money saved.

Human Resources is usually involved in some training and all disciplinary measures. Unwarranted discipline should be avoided, and this should be part of the role of HR.

The Improvement Team Leader may have a small staff including:

- A Trending Technician

- Facilitators (full-time, part-time, or both)

- A Technical Writer

- Admin/IT Support for Software

How is this improvement program implemented? That’s covered in Book 2:

TapRooT® Root Cause Analysis Implementation – Changing the Way Your Company Solves Problems.

By forming a team and using the same root cause analysis tool across all the improvement efforts of your company or site, you:

- Establish a single tool for everyone to be trained on.

- Establish a single system for management to understand (including a single style of incident presentation for production issues, schedule and budget problems, safety incidents, quality issues, or equipment failure reports).

- Make everyone communicate in the same language.

- Establish a single framework for all your human performance and equipment failure analysis.

- Make trending and reporting on improvement progress understandable and reliable.

It is amazing how much standardization can help an improvement initiative. And it is amazing how TapRooT® Root Cause Analysis can work across:

- Human Performance Issues,

- Quality Issues

- Fatalities, Serious Safety Incidents, and Safety Precursor Incidents,

- Equipment Failures,

- Production Problems,

- Budget Overruns, or

- Schedule Slippages (just to name a few).

Imagine how much wasted improvement effort can be saved. Imagine how much easier it will be for management to stay informed and manage the improvement initiatives.

Human Performance Improvement

So far, we have talked about combining improvement efforts across different silos in a company or facility. But there is a single factor that crosses all departmental boundaries – Human Performance.

How can you improve human performance? That is the topic of our Stopping Human Error Course that should be a part of any improvement program.

What’s in the Stopping Human Error Course? Here is the course outline…

Course Outline

Day 1 (8:00am to 5:00pm)

- Foundations of Improving Human Performance

- Human Performance – What Should You Expect?

- Three Human Reliability Best Practices

- Mistake Proofing

- Resilience

- Safeguards

- Using TapRooT® Root Cause Analysis for Reactive Problem Analysis

- Human Performance Improvement Technology (Catch Your Own Mistakes)

- STAR

- Questioning Attitude

- Attention to Detail

- Time Out

- Error Traps & Precursors

- Validate Assumptions

- Work Direction/Finding Error Likely Situations

- Pre-Job Hazard Analysis

- Pre-Job Brief

- Personal Safety Assessment

- Post-Job Brief

- Training

- Systematic Approach to Training

- Using Procedures to Improve Human Performance

- Procedures Best Practices

- Procedure Use and Adherence

- Place Keeping

Day 2 (8:00am to 5:00pm)

- Communications

- 3-Way Communication

- Do Not Disturb Sign

- Management System

- Conservative Decision Making

- Stopping Normalization of Deviation

- MOC

- Quality Control

- Independent Verification

- Concurrent Verification

- Human Factors Engineering

- Best Practices (Spot Bad Practices)

- Proactive Use of CHAP

- Hazard/Target Elimination or Substitution

- Improvement Exercise

- What Should You Improve/Which Tools Will Work Best for You?

- Sample Plan

- Present Your Plan (Benchmarking/Feedback)

You will leave this course with a clear understanding of methods to improve human performance and a custom plan to apply these methods at your company to achieve great gains in safety, quality, or operational and maintenance performance (all of which depend on human performance).

CLICK HERE for more course information. CLICK HERE for upcoming course dates and locations. Or CLICK HERE to schedule a course at your site.

What’s Next?

Would you like help planning your overall improvement program? We would be happy to help. Call us at 865-539-2139 or CLICK HERE to contact us.

Our Implementation Advisors will be happy to discuss your unique needs, develop a Roadmap to Success, and set up an Executive Briefing for your management.